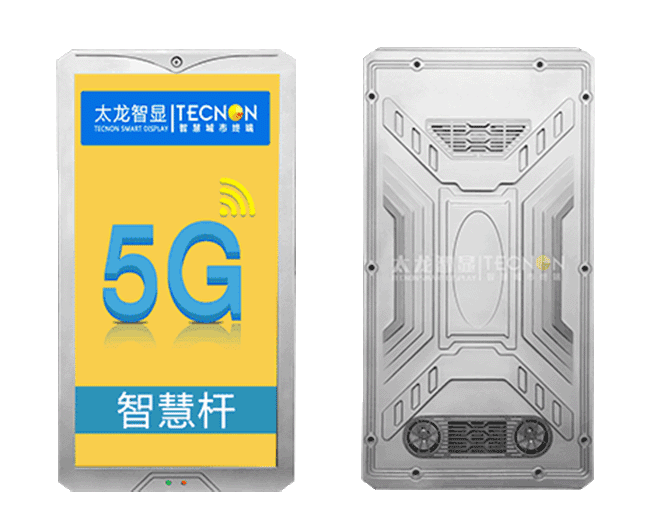

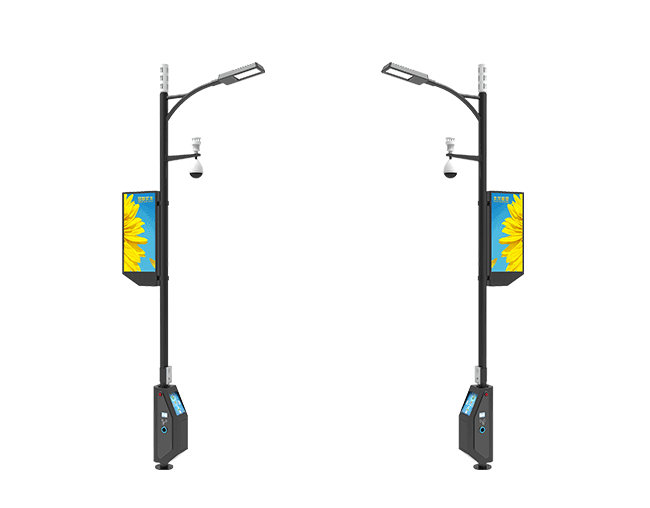

Analysis of the LED light pole screen cabinet : How to ensure safety and reliability in outdoor environments?

As the core carrier of smart city construction, the cabinet strength of the LED light pole screen is directly related to public safety and equipment life. In coastal cities with frequent typhoons, the equipment failure rate due to cabinet deformation is as high as 12% each year, while the failure rate of equipment that meets the strength standard can be controlled within 0.5%.

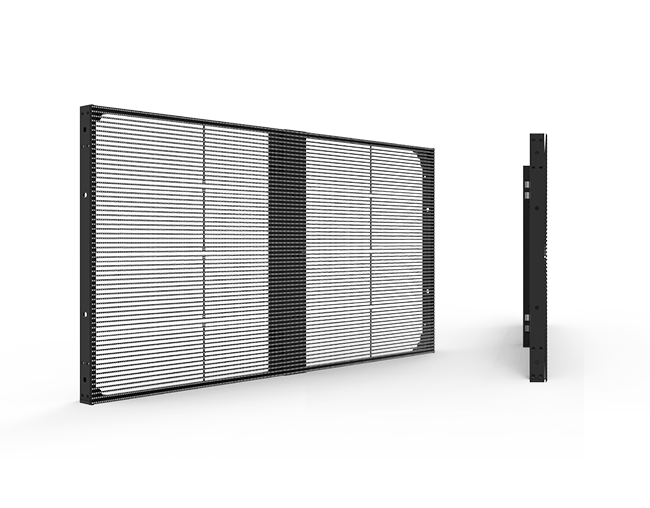

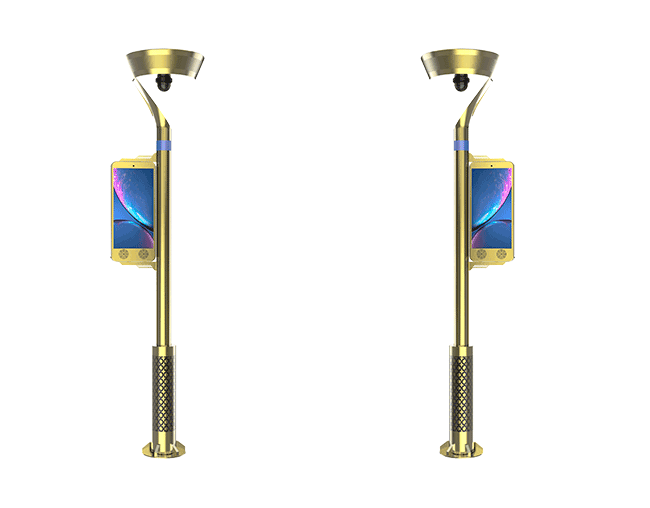

Aluminum alloy 6063-T5 is the mainstream cabinet material, and its tensile strength must be ≥160MPa and its yield strength must be ≥110MPa. The wall thickness of the central module cavity processed by CNC should be more than 3.5mm to ensure that the structure remains stable under extreme temperature differences from -40℃ to +85℃. The tensile strength of the 304 stainless steel bracket must be ≥520MPa, the fasteners must meet the 8.8 grade standard, and the pre-tightening torque is controlled at 25N·m±10% to avoid stress concentration.

In the Xiamen Ring Road Smart Street Light Project, the display screen box made of 6 series aluminum alloy remained intact during the attack of the 17-level typhoon "Mikra", while the damage rate of equipment that did not meet the standard in the same section reached 37%. This confirms the core value of the ASTM B221 standard on the mechanical properties of metal materials.

The box structure must be verified by finite element analysis (FEA) to ensure that the deformation is less than L/200 at a wind speed of 55m/s. The reinforcement ribs are arranged in a radial pattern with a spacing of no more than 150mm, and the thickness to the box wall thickness ratio reaches 1:1.2. The back panel mounting holes adopt a honeycomb array design, and the opening rate is controlled between 30%-40%, which not only ensures heat dissipation but also maintains structural rigidity.

According to the GB/T31446 standard, the light pole screen must pass a 30-minute sinusoidal fixed-frequency vibration test (frequency 5Hz-500Hz, acceleration 5g), as well as 20 1m height drop tests. In the actual measurement in Hengqin, Zhuhai, the maximum displacement of the qualified equipment in the wind tunnel test equivalent to a level 16 typhoon was only 2.3mm, far below the national standard limit of 5mm.

In the wave of smart street light construction, the box strength of the LED light pole screen has become a core indicator of product competitiveness. From the corrosion-resistant design of the Qingdao Jiaozhou Bay Bridge, to the earthquake-resistant solution of the Sichuan-Tibet Highway, to the typhoon-resistant verification of the Guangdong-Hong Kong-Macao Greater Bay Area, every technological breakthrough is redefining the safety standards of outdoor display equipment. Choosing products that have passed a full set of environmental tests such as GB/T2423 and IEC60068 is not only a quality assurance, but also a responsibility for urban safety.